Introduction to XRF Technology in Metal Assessment

X-ray fluorescence (XRF) technology has changed the metal assessment game forever.

Professionals who deal in precious metals celebrate this method because it is non-destructive and does not damage the item being tested.

XRF's ability to quickly identify and quantify metal compositions enhances quality control and compliance in manufacturing and precious metal trading. Isn’t that a game-changer?

Only the best gold buyers incorporate this extremely helpful tech in their valuations. It is accurate, quick, and non-destructive.

Gold Rush Lakewood is a premier buyer of gold, silver, platinum, and palladium in Colorado and Texas. We use the latest technology and assessment methods to provide the most accurate valuation of your items so you can maximize your sales!

Key Takeaways

- Accuracy: XRF provides precise measurements of metal compositions.

- Speed: Rapid analysis saves time and boosts productivity.

- Versatility: Suitable for various metals, including gold, silver, platinum, and palladium.

- Non-destructive: Analyzes metals without causing damage.

- Comprehensive: Capable of detecting multiple elements in a single test.

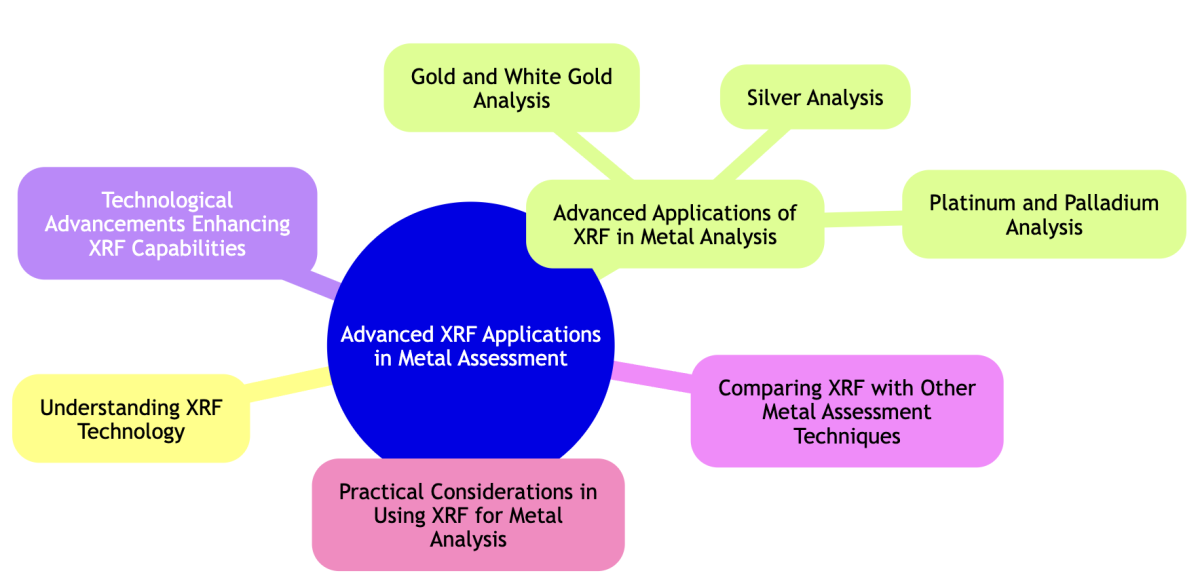

Understanding XRF Technology

XRF technology works by directing X-rays at a metal sample.

The X-rays excite the atoms within the sample, causing them to emit fluorescent X-rays at characteristic energies.

These emitted X-rays are then measured to determine the metal’s composition. XRF's impressive precision makes it a trusted tool in various industries.

The process involves several key steps:

- Sample Preparation: Clean and prepare the sample surface.

- Calibration: Use standards to calibrate the XRF device.

- Measurement: Direct X-rays at the sample and measure the emitted fluorescence.

- Data Analysis: Analyze the spectrum to determine the metal's composition.

- Reporting: Generate a detailed report with the findings.

Precision of XRF Analysis for Different Metals

|

Metal |

Common Impurities |

Precision Level |

|

Gold |

Copper, Silver |

± 0.01% |

|

Silver |

Copper, Lead |

± 0.05% |

|

Platinum |

Palladium, Iridium |

± 0.02% |

|

Palladium |

Platinum, Rhodium |

± 0.02% |

|

White Gold |

Nickel, Zinc |

± 0.03% |

Advanced Applications of XRF in Metal Analysis

Gold and White Gold Analysis

XRF technology excels in analyzing gold and white gold.

For gold, XRF accurately determines its purity by measuring its concentration and identifying any alloying elements like copper or silver. This precise analysis helps jewelers and traders verify the authenticity and quality of gold items.

White gold, often alloyed with metals like nickel, palladium, or zinc, presents different assessment challenges. XRF effectively distinguishes between these alloying elements, so the assessor knows the composition meets industry standards and consumer expectations.

XRF can detect trace amounts of impurities - we see everything!

Silver Analysis

XRF can also provide accurate silver analysis.

It identifies silver's purity level by detecting alloying elements such as copper or lead.

This analysis is crucial for industries where silver's purity impacts its performance, like electronics or jewelry.

The technology's non-destructive nature allows for continuous quality checks without damaging the product.

XRF also helps in sorting silver items based on their purity, which is particularly useful in recycling operations. By providing detailed compositional data, XRF helps maintain high standards and meet regulatory requirements by providing detailed compositional data.

Platinum and Palladium Analysis

Shifting focus to platinum and palladium - these metals are often used in high-precision applications like catalytic converters and fine jewelry.

XRF identifies the exact composition and detects any impurities, guaranteeing the metals meet stringent quality standards.

Technological Advancements Enhancing XRF Capabilities

Recent advancements have significantly enhanced XRF technology.

Improved detectors now offer higher resolution and sensitivity, allowing for more precise measurements.

Software innovations provide better data analysis and reporting capabilities. Overall, the technology has become more user-friendly and efficient. Key innovations include:

- Enhanced Detectors: Provide greater accuracy and lower detection limits.

- Automated Calibration: Simplifies the calibration process, saving time.

- Portable Devices: Increase flexibility and usability in various environments.

- Advanced Software: Offers sophisticated data analysis and reporting tools.

- Integrated Systems: Combine XRF with other analytical techniques for comprehensive analysis.

Comparing XRF with Other Metal Assessment Techniques

XRF, Optical Emission Spectroscopy (OES), and Laser-Induced Breakdown Spectroscopy (LIBS) each offer unique benefits for metal assessment.

XRF is renowned for its non-destructive nature and versatility. It accurately identifies a broad range of elements in various metals.

OES excels in detecting trace elements with high precision, making it ideal for detailed compositional analysis.

LIBS, on the other hand, provides rapid, in-situ analysis by vaporizing a small portion of the sample with a laser, which is useful for field applications.

Comparison of Metal Assessment Techniques

|

Technique |

Accuracy |

Speed |

Cost |

Applications |

|

XRF |

High |

Fast |

Moderate |

Jewelry, recycling, manufacturing |

|

OES |

Very High |

Moderate |

High |

Metallurgy, quality control |

|

LIBS |

Moderate |

Very Fast |

Moderate |

Field analysis, quick screening |

Practical Considerations in Using XRF for Metal Analysis

Using XRF effectively involves several practical steps.

Proper sample preparation is key to obtaining accurate results. Clean and smooth sample surfaces improve measurement precision.

Regular calibration of the XRF device ensures consistent performance.

Users must also stay updated with software improvements to leverage new features and enhancements.

- Equipment Maintenance: Regularly clean and inspect the XRF device.

- Calibration: Use certified standards to calibrate the device frequently.

- User Training: Ensure operators are well-trained to handle the equipment and interpret results accurately.

- Environmental Factors: Consider temperature and humidity conditions, as they can affect measurements.

- Data Management: Implement robust data management practices for recording and analyzing results.

Accurate Precious Metal Assessments with Gold Rush Denver - Gold Rush Denver

When it is time to sell gold to a local dealer (or any other precious metal) be sure to work with an establishment that has not only fantastic reviews (like Gold Rush) but also the latest assessment methods, such as XRF.

Professional metal dealers know that there is no substitute for precision in this line of work. Our reputation hangs on our accuracy. That is why Gold Rush is committed to staying on the cutting edge of precious metal assessments.

Whether assessing gold, silver, platinum, or other metals, XRF delivers reliable and comprehensive results.

Gold Rush has locations all over the greater Denver area. We invite you to use us as your go-to resource to Sell Diamonds and gold in Denver. Call with questions or find us online for more information!